Cell Cyclers

Expandable List

Digatron 8-Channel Cycler

Model#MCT 75-0/5-8ME

Location: MARC 130 (CMHT)

Features:

- 8-Ch, 75 A/Ch., 0-5 V

- Parallel up to 600 A

- V/I Accuracy: ± 0.05% of full scale

Resources:

- Digatron Getting Started Guide

- Manuals and Datasheet: Digatron

Arbin 8-Channel Cycler

LBT21084-0~5V-60/5/0.5/0.02A-8CH-208V3P

Location: MARC 130 (CMHT)

Features:

- 8-Ch., 60 A/Ch., 0-5 V

- Parallel channels for 480 A

- CAN interface for HIL test

- Current range: ± 60 A, 5 A, 500 mA, 20 mA

- V/I Accuracy: ± 0.02% of full scale

Resources:

-

- Arbin Getting Started Guide

- Manuals and Datasheet: Arbin

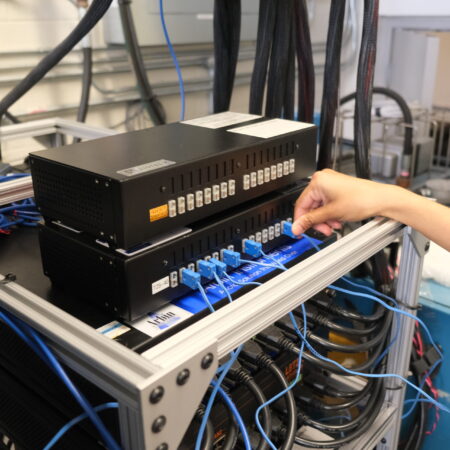

Arbin 32-Channel Cycler

LBT21084-0~5V-10/0.5/0.02/0.001A-32CH–208V3P

Location: MARC 130 (CMHT)

Features:

- 32-Ch., 10 A/Ch., 0-5 V

- Current range: ± 10 A, 500 mA, 20 mA, 1 mA

- V/I Accuracy: ± 0.02% of full scale

Resources:

-

- Arbin Getting Started Guide

- Manuals and Datasheet: Arbin

Arbin 16-Channel Cycler

LBT21084-0~5V-10/0.5/0.02/0.001A-16CH-120V

Location: MARC 130 (CMHT)

Features:

- 16-Ch., 10 A/Ch., 0-5 V

- Current range: ± 10 A, 0.5 A, 20 mA, 1 mA

- V/I Accuracy: ± 0.02% of full scale

Resources:

-

- Arbin Getting Started Guide

- Manuals and Datasheet: Arbin

Pack Cycler

Expandable List

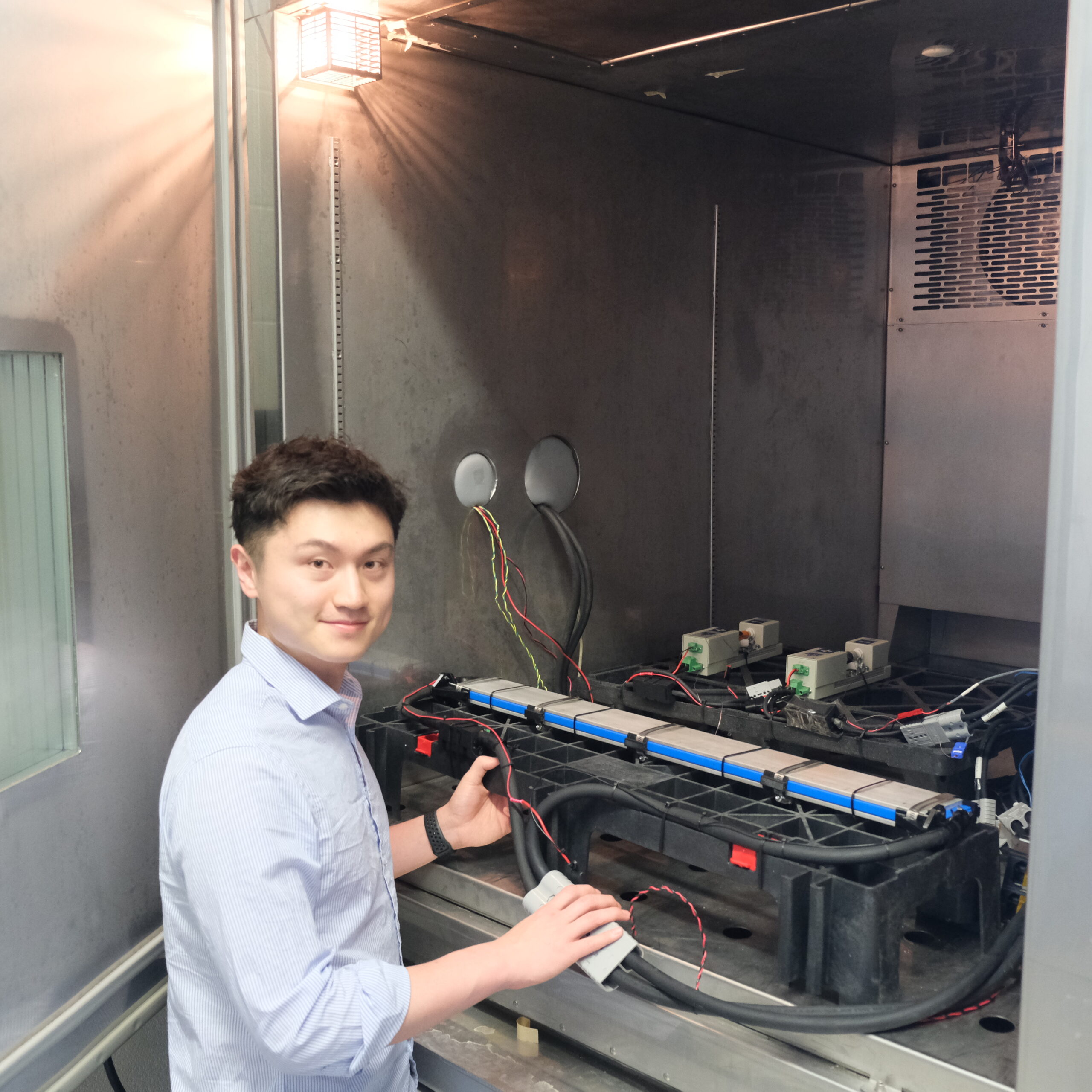

160 kW AVL-E Storage BTE160

160 kW AVL-E Storage BTE160

Model#GW200

Features:

- 1-Ch., 600 A., 8-800 V., 160 kW

- Integrated with a four-wheel dyno

- J1772 Combo, 500 A fast charge connector

List of Functions:

- Battery Cycler

- Battery Emulator

- Fast Charger

- Bi-directional DC power supply

Resources:

- AVL Getting Started Guide – Battery Cycler

- Manuals and Datasheets: AVL

J1772 Fast Charge Connector

Location: MARC 118

Features:

- Delivers up to 500 A of charging current.

- Liquid cooled, bidirectional.

Resources:

Thermal Chambers

Expandable List

Arbin Microthermal Chambers:

Model# MZTC

Location: MARC 130 (CMHT)

Features:

- Temperature Control: ±0.5°C

- Two MZTC units – 16 total microchambers

Resources:

- Manuals and Datasheet: Arbin MZTC

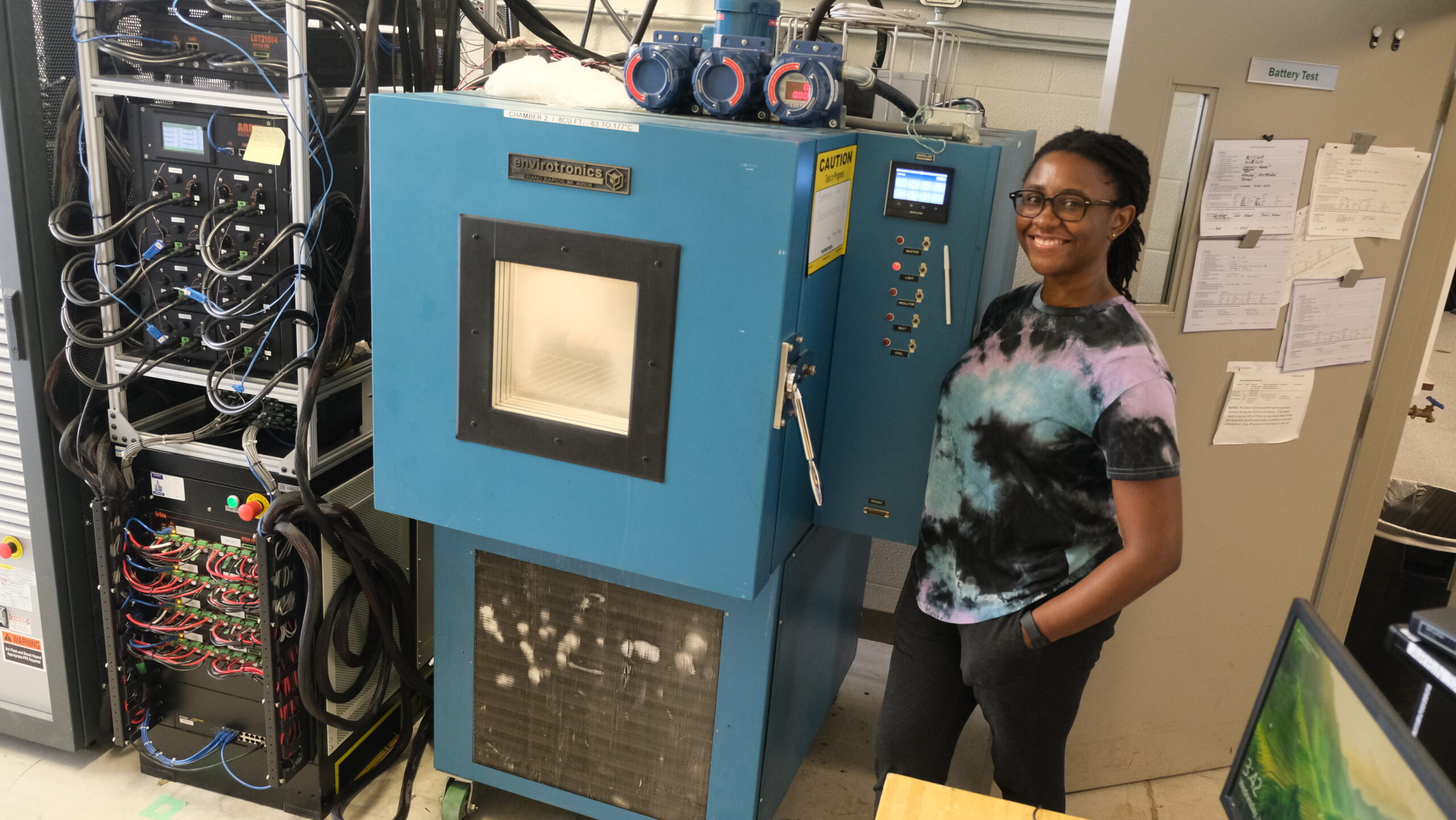

Envirotronics

Model# ET8-2-1.5

This chamber is equipped with gas sensors and a CO2 fire suppression system.

Location: MARC 130 (CMHT)

Features:

- Temperature control: ± 1ºC

- Chamber Controller: Watlow F4T

Resources:

- Manuals and Datasheet: Envirotronics

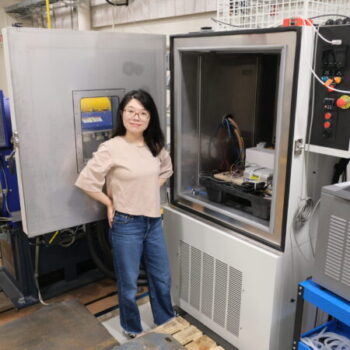

Envirotronics Environmental Test Chamber

Model# SH16

This chamber is equipped with gas sensors and a CO2 fire suppression system.

Location: MARC 130 (CMHT)

Features:

- Temperature control stability: ±1.1ºC.

- Chamber Controller: Systems Plus

Resources:

- Manuals and Datasheet: Envirotronics

Tenney Environmental

Model#TC20C2.0-A-F4T-B-ETO

Location: MARC 118

Features:

- Temperature control: ± 1ºC.

- Chamber Controller: Watlow F4T

Resources:

- Manuals and Datasheet: Tenney

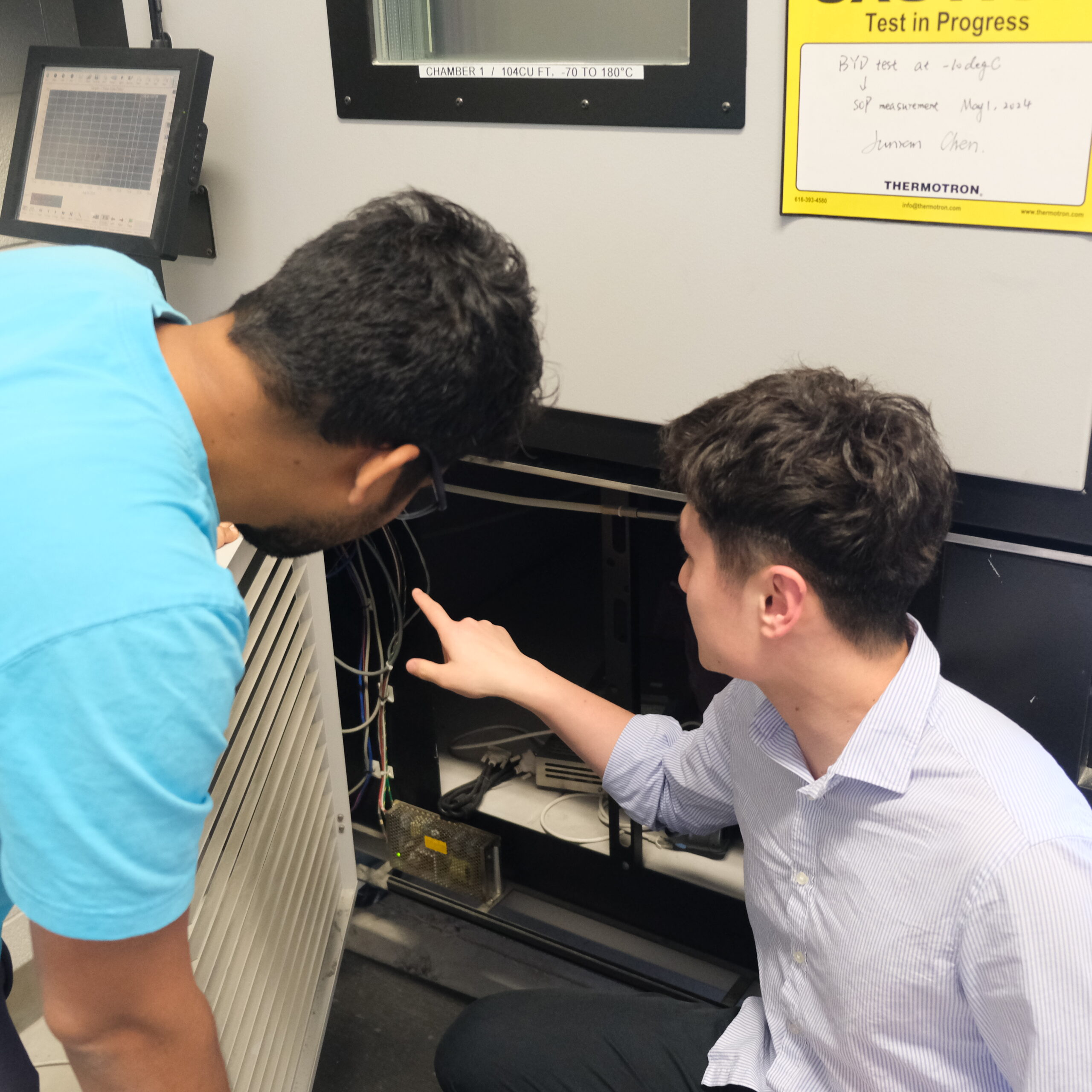

Thermotron

Model# SE-3000-6-6

Our largest thermal chamber can be controlled using temperature commands from D&V Cycler. This chamber is equipped with gas sensors and a CO2 fire suppression system.

Location: MARC 130 (CMHT)

Features:

- Temperature control stability: ±0.3°C

- Chamber Controller: Thermotron 8800

Resources:

-

- Manuals and Datasheet: Thermotron

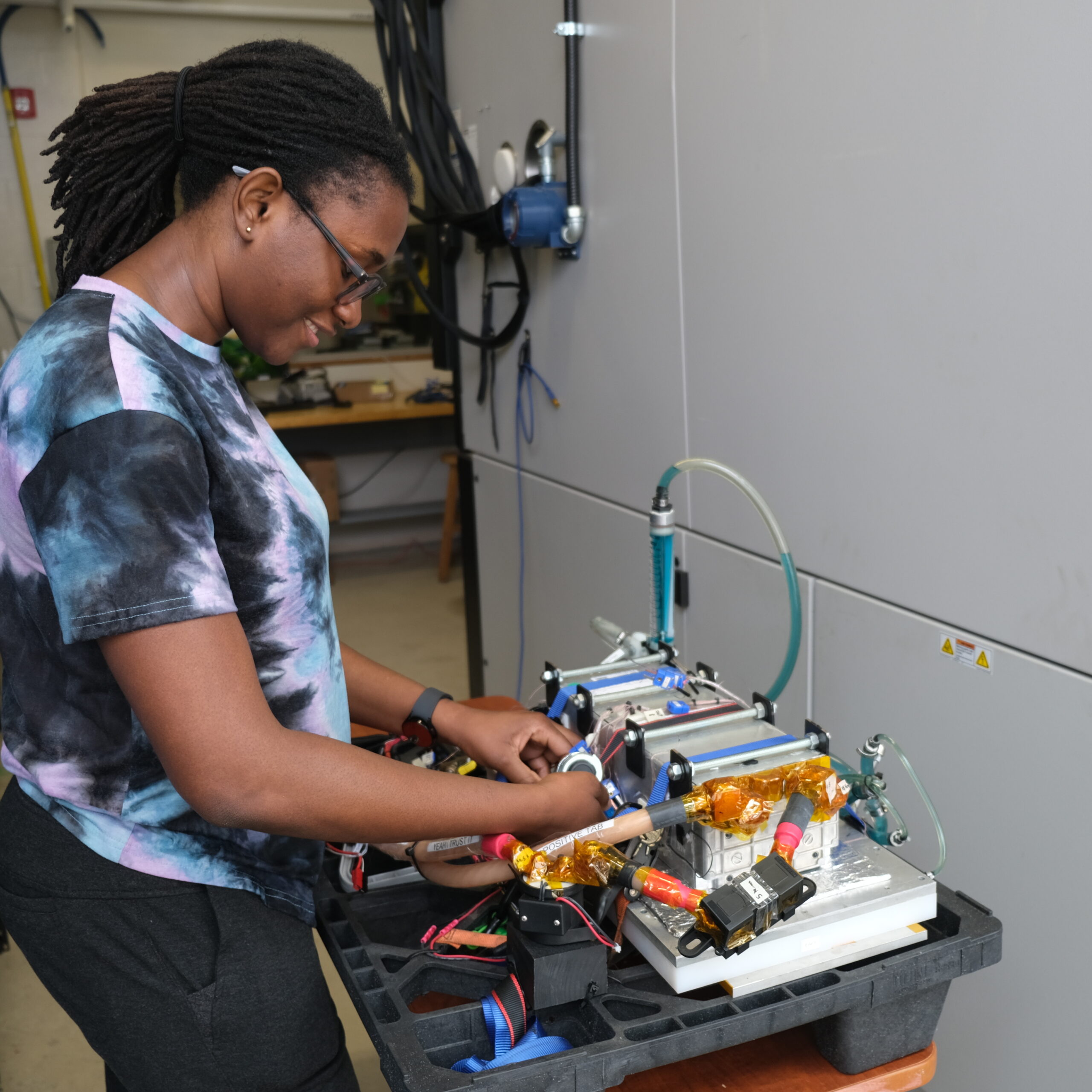

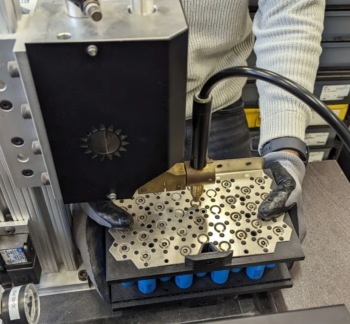

Preparing the blade cell for testing, ensuring all connections are properly secured

- Manuals and Datasheet: Thermotron

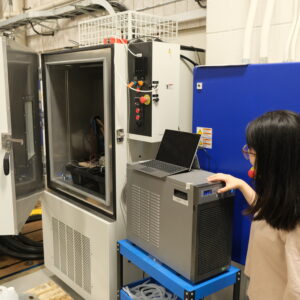

Liquid Chiller

Expandable List

1.5 kW PolyScience Liquid Chiller

Model# LS51MXA113C

Features:

- Temperature stability: ±0.1ºC

- 13.25 LPM (-20oC to 40oC)

- 1.5 kW cooling @ 30oC

- Serial control interface

- Ethylene glycol & water (50/50 mix)

Resources:

- Manual and Datasheet: PolyScience

24 kW ThermoFlex Recirculating Chiller

Model#ThermoFlex24000

Features:

- Temperature Stability: ±0.1ºC

- Turbine Pump (T9) 60 Hz – 102.2 LPM @ 3.4 bar

- -5oC to 90oC

- Water-cooled

Resources:

- Manual and Datasheet: ThermoFisher

Other Equipment

Expandable List

Flir E75 Thermal Camera

Features:

- Temperature Stability: ± 2oC accuracy

- 320 x 240 resolution

- Emissivity Correction

- Images and Video

- ResearchIR software tool

Resources:

- Manual and Datasheet: Flir E75

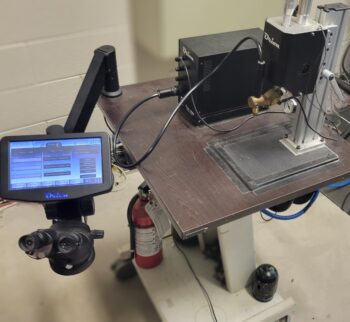

Sunstone Orion 250i Arc-Welder

Location: MARC 125 (CMHT)

Features:

- 0.1 – 250 Joules of power

- Pulse-Arc and Resistance Technology

- High Frequency Agitation

- Rapid Fire Pulsing

- Space-Saving Microscope with Optical Shutter, LED Lights, and 5x / 10x Magnification

Resources:

- Sunstone Welder Getting Started Guide

- Manuals and Datasheets: Sunstone Orion 250i

Parallel Gap Weld Head

Model#WH2250A

Location: MARC 125 (CMHT)

Features:

- Pneumatic Air-actuation

- Provides precision and repeatability

- Fine control of weld pressure from 1 to 15 lbs

- Low electrode inertia for fast follow-on pressure

Resources:

- Sunstone Welder Getting Started Guide

- Manual and Datasheet: Sunstone Weld Head (for similar weld head)

Orion BMS 2

Orion BMS 2

Features:

- Supports 4 – 180 cells in series per BMS unit, with 25 mS cell voltage polling

- Intelligent cell balancing

- High immunity to EMI and other noise

- 2x Programmable CANBUS Interfaces

- Integrated support for J1772 quick chargers

- Thermal management controls for battery heating and cooling

Resources:

- Orion BMS Getting Started Guide

- Manual and Datasheet: Orion BMS 2

Orion BMS 2 Jr.

Orion BMS 2 Jr.

Features:

- Supports 1-16 cells in series, designed for packs up to 48 V nominal, 60 V max.

- Integrated low loss passive cell balancing to within 5 mV.

- High resistance to EMI with accurate data polling.

- CANBUS interface for diagnostics and integration.

- Three thermistor inputs for temperature sensing, additional monitoring is possible via thermistor expansion module.

Resources:

- Orion BMS Getting Started Guide

- Manual and Datasheet: Orion Jr. BMS 2

National Instruments DAQ Hardware

Location: MARC 130

Features:

- NI 9171 Compact DAQ Chassis

- NI 9212 high accuracy isolated channel-to-channel thermocouple inputs

- NI 9862 high speed CAN interface

Resources:

Datasheets and Manuals: Temperature Sensing and CAN Tool